In the dynamic environment of construction sites, ensuring safety and security is paramount. One of the key elements contributing to these objectives is scaffolding mesh, which serves multiple functions beyond just supporting workers. This article covers the importance of scaffolding mesh, various types, installation practices, regulatory standards, and future trends in technology related to scaffolding safety and privacy.

Understanding the Importance of Scaffolding Mesh

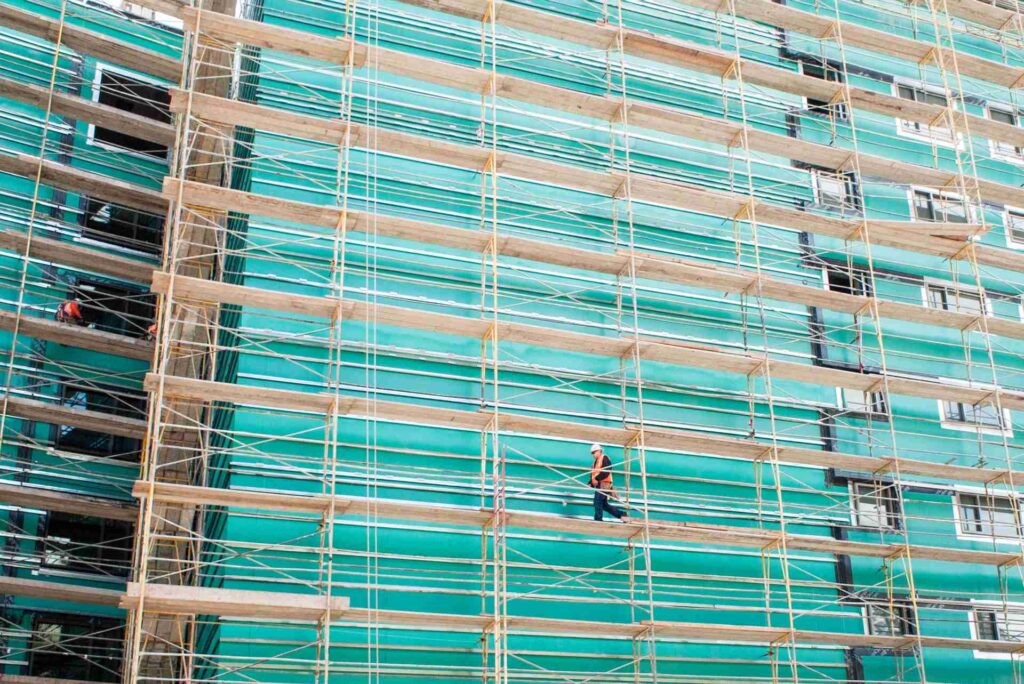

Scaffolding mesh is a crucial addition to any construction site, playing an integral role in maintaining safety and efficiency. It provides a physical barrier that protects workers and passersby from falling debris and facilitates a more organized and secure environment.

The Role of Scaffolding Mesh in Construction Safety

The primary purpose of scaffolding mesh is to enhance the safety of a construction site. By acting as a safeguard against falling objects, it minimizes the risk of accidents that could lead to serious injuries or fatalities. Studies have shown that job sites employing scaffolding mesh report significantly fewer incidents related to falling debris.

Additionally, scaffolding mesh can also provide wind resistance. In high-rise projects, the effects of strong winds can pose a serious risk, and scaffolding mesh helps stabilize the site. This ensures that both the structure being built and the workers are kept safe from sudden gusts. Furthermore, the mesh’s design often includes features that allow for better airflow, which can help in reducing the buildup of dust and debris, contributing to a cleaner and healthier work environment.

Privacy Benefits of Using Scaffolding Mesh

Beyond safety, scaffolding mesh also offers privacy benefits for both the construction workers and those living nearby. The mesh acts as a visual barrier, blocking the view into the construction site. This is particularly important in urban areas, where the proximity of neighbors can lead to complaints about noise or visual disturbances.

Moreover, safeguarding the activities happening on site helps in maintaining a sense of order. It protects sensitive information or confidential development plans from prying eyes. Thus, scaffolding mesh serves to create a controlled environment where work can be conducted without interruptions. In addition, the use of colored or patterned scaffolding mesh can enhance the aesthetic appeal of a construction site, transforming what might be seen as an eyesore into a more visually pleasing structure. This not only helps in reducing complaints from the community but can also foster a more positive perception of the construction project as a whole.

Furthermore, the installation of scaffolding mesh can also contribute to environmental sustainability. Many modern scaffolding meshes are made from recyclable materials, which aligns with the growing emphasis on eco-friendly practices in construction. By opting for sustainable mesh options, construction companies can demonstrate their commitment to reducing their carbon footprint while simultaneously enhancing site safety and privacy. This multi-faceted approach not only benefits the immediate project but also promotes a broader culture of responsibility within the industry.

Types of Scaffolding Mesh and Their Uses

There are various types of scaffolding mesh, each with unique features tailored to specific applications. Selecting the right type can significantly influence the overall effectiveness and safety of the scaffolding system.

Flame Retardant Scaffolding Mesh

Flame retardant scaffolding mesh is designed to mitigate the risk of fire on construction sites. Made from materials treated with flame retardant chemicals, this type of mesh can be invaluable in environments where welding or cutting operations may occur.

In addition to its safety features, flame retardant mesh also complies with many fire safety regulations, thereby ensuring that construction companies meet legal requirements. The implementation of this type of mesh reinforces a construction site’s commitment to not only worker safety but also to following industry standards. Furthermore, the use of flame retardant mesh can enhance the overall reputation of a construction firm, as it demonstrates a proactive approach to risk management and safety compliance, potentially attracting more clients who prioritize safety in their projects. Find more about flame at https://www.flame.edu.in/about-flame

High Visibility Scaffolding Mesh

High visibility scaffolding mesh is another essential type commonly used in construction. Often featuring bright colors and patterns, this mesh provides high visibility, reducing the likelihood of accidents caused by machinery or personnel not seeing the scaffolding infrastructure.

This type of mesh is particularly beneficial in hazardous environments, where visibility can often be compromised. The bright colors alert workers and bystanders alike, ensuring that everyone is aware of the boundaries and potential hazards of the construction site. Additionally, high visibility mesh can be instrumental in nighttime operations or in low-light conditions, where the risk of accidents increases significantly. By incorporating reflective materials or LED lighting into the design, this mesh can further enhance safety, making it an indispensable tool for construction teams working around the clock.

Installation and Maintenance of Scaffolding Mesh

Installing scaffolding mesh effectively is critical to ensuring its performance and longevity. Proper installation can prevent up to 75% of issues related to mesh safety.

Proper Installation Techniques for Scaffolding Mesh

Proper installation involves several key steps, including ensuring that the mesh is securely attached to the scaffolding frame. Using adequate fasteners and following manufacturer guidelines is essential for achieving a safe installation.

It’s also crucial to assess the environment before installation. Weather conditions, wind speeds, and other site-specific factors should guide the choice of mesh type and installation technique. Ensuring tautness in the mesh can assist in avoiding flapping that may compromise its integrity. Additionally, it is advisable to conduct a thorough site survey to identify potential hazards, such as overhead power lines or nearby structures, which could influence the installation process. This proactive approach not only enhances safety but also promotes a smoother workflow during the installation phase. To find more about hazards click here.

Regular Maintenance and Inspection of Scaffolding Mesh

Like any other safety device on a construction site, scaffolding mesh requires regular maintenance and inspection. Routine checks help identify any wear and tear that could hinder the mesh’s effectiveness.

Inspecting for holes, frays, and other damage is important to maintain both safety and privacy on-site. When issues are discovered, timely intervention through repair or replacement ensures continued protection for workers and the surrounding community. Furthermore, it’s beneficial to keep a detailed log of inspections and maintenance activities, which can serve as a valuable reference for future projects and audits. This documentation not only helps in tracking the mesh’s lifespan but also reinforces compliance with safety regulations and standards, ultimately fostering a culture of safety on the job site.

Regulatory Standards for Scaffolding Mesh

Adhering to regulatory standards is vital for construction sites to operate legally and safely. Various organizations provide guidelines and rules that construction companies must follow regarding scaffolding safety.

OSHA Standards for Scaffolding Mesh

The Occupational Safety and Health Administration (OSHA) outlines specific standards for scaffolding and associated components, including mesh. These standards cover aspects like materials used, load capacities, and installation practices, ensuring safety on job sites.

Failure to comply with these standards can lead to significant penalties and fines, along with increased risks of accidents. Construction companies, therefore, prioritize staying informed about OSHA regulations to promote a safer work environment. Regular training sessions and workshops are often conducted to ensure that all workers understand the importance of these standards and how to implement them effectively. Furthermore, the use of certified scaffolding mesh that meets OSHA specifications is crucial, as it not only protects workers but also minimizes liability for the company.

International Standards for Scaffolding Safety

Beyond national regulations, international standards also play a crucial role in scaffolding safety. Organizations like the International Organization for Standardization (ISO) establish guidelines that help promote safe practices globally.

Adapting to these international standards not only improves safety on-site but can also enhance a construction company’s reputation and competitiveness in the global marketplace. Compliance with varied regulations ensures that a company can undertake projects in international settings without hindrance. Additionally, many countries have their own specific regulations that align with ISO standards, which necessitates a thorough understanding of local laws and practices. This global perspective not only fosters a culture of safety but also encourages innovation in scaffolding design and materials, leading to more efficient and sustainable construction practices worldwide.

Future Trends in Scaffolding Mesh Technology

The field of scaffolding mesh technology continues to evolve, bringing innovation and improved safety solutions to the industry. Understanding these trends is vital for construction companies looking to stay ahead.

Innovations in Scaffolding Mesh Material

Emerging technologies are leading to the development of advanced materials for scaffolding mesh that are lighter, stronger, and more durable. Innovations including the integration of composite materials and new weaves are making scaffolding mesh more efficient.

These innovations can significantly reduce the weight of scaffolding systems, making them easier to transport and install while still maintaining their safety attributes. Additionally, materials that are resistant to extreme weather conditions are becoming increasingly common. For instance, the use of UV-resistant coatings not only extends the lifespan of the mesh but also ensures that it remains functional and safe under prolonged exposure to sunlight. This is particularly important for projects in regions with harsh climates, where traditional materials may degrade more quickly.

The Impact of Technology on Scaffolding Safety

Technology is also playing a vital role in enhancing safety protocols related to scaffolding mesh. Advanced monitoring systems equipped with sensors can detect the condition of the mesh in real-time, alerting workers to potential hazards before they become serious issues.

Furthermore, training and resources for workers are increasingly being provided through virtual reality (VR) and augmented reality (AR) applications, helping crews to understand and implement safety measures more effectively. These technologies are transforming how construction sites manage safety and privacy risks related to scaffolding mesh. In addition to VR and AR, the use of drones for site inspections is gaining traction, allowing for a comprehensive overview of scaffolding integrity without putting workers at risk. This aerial perspective can quickly identify wear and tear or misalignment, ensuring that any necessary adjustments are made promptly.

Moreover, the integration of artificial intelligence (AI) into project management software is streamlining the planning and execution phases of construction. AI can analyze data from past projects to predict potential safety issues, optimize material usage, and enhance overall workflow efficiency. By leveraging these advanced technologies, construction companies can not only enhance safety measures but also improve productivity and reduce costs associated with accidents and delays.

Read about temporary scaffolding at: Temporary Scaffolding